American companies are losing, and struggling for a share in the home market. According to the German VDMA group, in 1995 they satisfied 81% of the demand for plant equipment in the US. In 2015, the figure was only 63%.

Criticism of President Donald Trump, who is calling to produce in the US and forget import, has forced many companies to increase investment in local production capacities. However, this can lead to an increase in imports of industrial equipment that have no counterparts in the US.

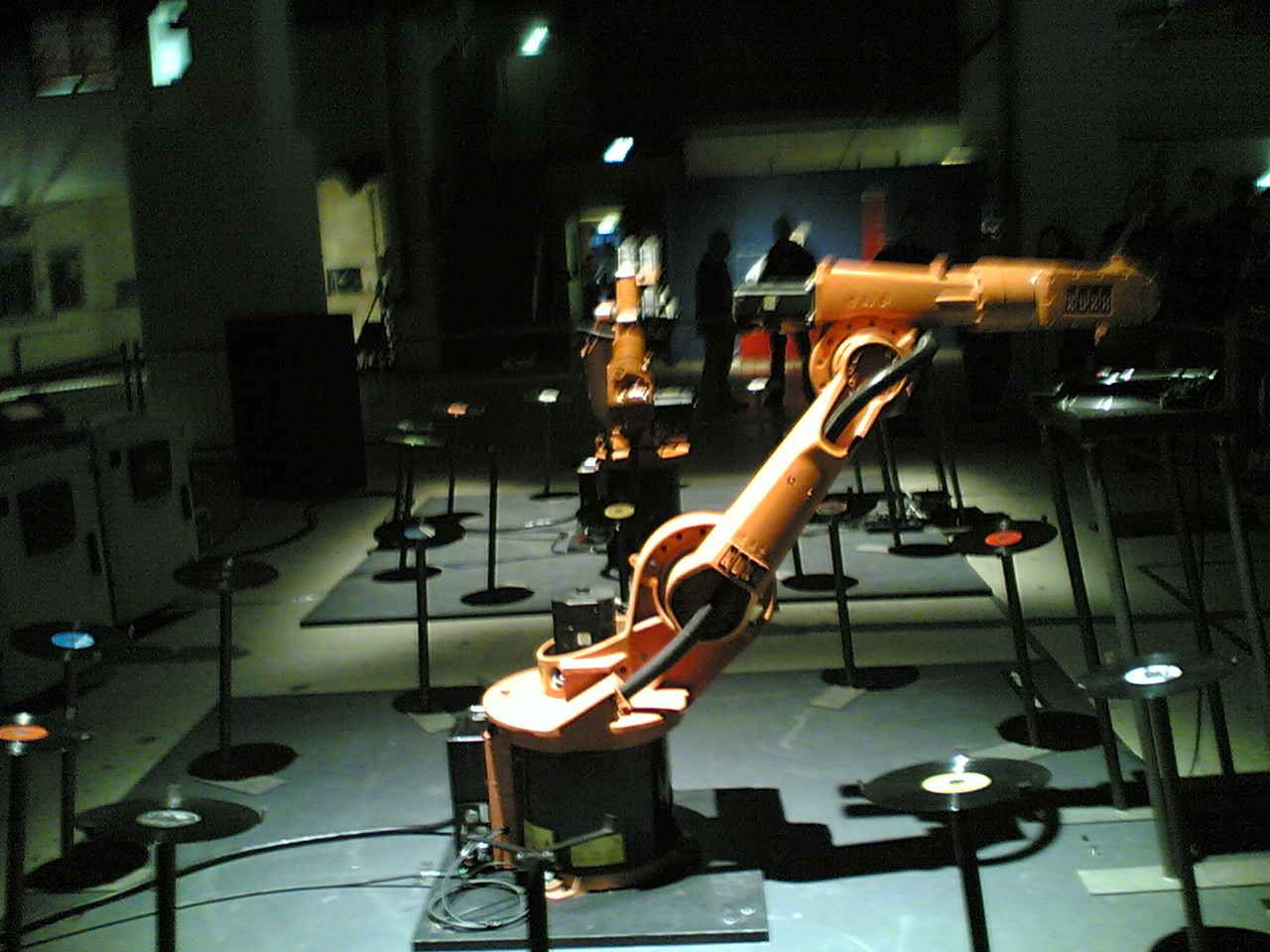

China has actively joined the race of innovations. The national strategy Made in China 2025 suggests that the PRC should achieve leadership in advanced production technologies in part through aggressive acquisition of foreign companies. An example of such a transaction is the last year's purchase of German manufacturer of industrial robots Kuka by Chinese company Midea Group.

The US dominated the market in 1970, when the advanced technologies in the field of industrial equipment were heavy machine tools. According to the International Robotics Federation, the first industrial robot, the two-ton Unimate, was made in Connecticut, and was installed at the General Motors (GM) plant in New Jersey in 1961. GM and Ford Motor tested industrial robots throughout the 1970. In 1982, GM set up a joint venture with Fanuc.

However, 1980 brought a decline in industrial production to the United States, says a study by Rand Corp. In 1993, 70% of machine-building enterprises were closed. The fall in demand for equipment extended for the 21st century. In addition, the industrial downturn led to a reduction in the need for qualified equipment manufacturers, which resulted in a brain drain to foreign companies, subsequently reinforcing the technological backwardness of the United States.

At the same time, European and Japanese governments were actively funding R&D, and manufacturers of various products, from drugs to cars, demanded increasingly specialized systems from local engineering companies.

Financial difficulties forced GM to sell Fanuc its share in the joint venture in 1992. Today, Fanuc delivers industrial robots to companies from a variety of industries, including GM itself.

The manufacturer of Tesla electric vehicles, which is often cited as an example of a high-tech American company, also imports industrial robots. The company's plant in California is equipped with Kuka manipulators. Recently, Tesla acquired German company Grohmann, which specializes in automation of plants. To build and equip a new plant in Nevada, Tesla needed "the best specialists in developing automatic production systems", the company said in a statement.

American companies are strong when it comes to development and production of sensors for robots that allow automatic production systems to respond to changing environments, and not just perform repetitive actions. President of Association for Advancing Automation Jeff Burnstein believes that small American technology companies have a powerful potential for innovative development in the field of production automation.

source: wsj.com

Criticism of President Donald Trump, who is calling to produce in the US and forget import, has forced many companies to increase investment in local production capacities. However, this can lead to an increase in imports of industrial equipment that have no counterparts in the US.

China has actively joined the race of innovations. The national strategy Made in China 2025 suggests that the PRC should achieve leadership in advanced production technologies in part through aggressive acquisition of foreign companies. An example of such a transaction is the last year's purchase of German manufacturer of industrial robots Kuka by Chinese company Midea Group.

The US dominated the market in 1970, when the advanced technologies in the field of industrial equipment were heavy machine tools. According to the International Robotics Federation, the first industrial robot, the two-ton Unimate, was made in Connecticut, and was installed at the General Motors (GM) plant in New Jersey in 1961. GM and Ford Motor tested industrial robots throughout the 1970. In 1982, GM set up a joint venture with Fanuc.

However, 1980 brought a decline in industrial production to the United States, says a study by Rand Corp. In 1993, 70% of machine-building enterprises were closed. The fall in demand for equipment extended for the 21st century. In addition, the industrial downturn led to a reduction in the need for qualified equipment manufacturers, which resulted in a brain drain to foreign companies, subsequently reinforcing the technological backwardness of the United States.

At the same time, European and Japanese governments were actively funding R&D, and manufacturers of various products, from drugs to cars, demanded increasingly specialized systems from local engineering companies.

Financial difficulties forced GM to sell Fanuc its share in the joint venture in 1992. Today, Fanuc delivers industrial robots to companies from a variety of industries, including GM itself.

The manufacturer of Tesla electric vehicles, which is often cited as an example of a high-tech American company, also imports industrial robots. The company's plant in California is equipped with Kuka manipulators. Recently, Tesla acquired German company Grohmann, which specializes in automation of plants. To build and equip a new plant in Nevada, Tesla needed "the best specialists in developing automatic production systems", the company said in a statement.

American companies are strong when it comes to development and production of sensors for robots that allow automatic production systems to respond to changing environments, and not just perform repetitive actions. President of Association for Advancing Automation Jeff Burnstein believes that small American technology companies have a powerful potential for innovative development in the field of production automation.

source: wsj.com