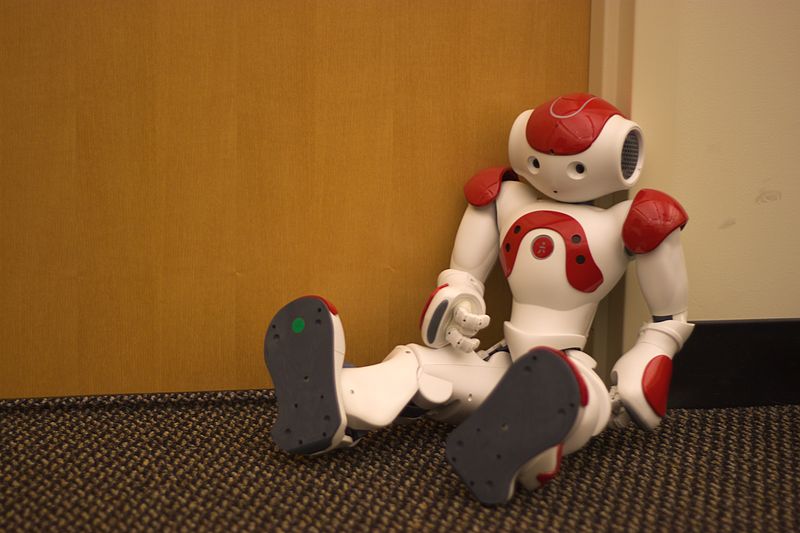

Aircraft manufacturers are lagging behind the automakers in using robotics. The lower volume and a longer production cycle makes deriving profit from robots way more difficult. But robots that can work together with people can make a difference. Together with the Japanese Joint Robotics Laboratory, Airbus is implementing a four-year research project on the development of lightweight and agile humanized robots that can perform complex production tasks. Furthermore, they will be equipped with sensors to prevent damage to humans. This machine cannot replace a worker, but Airbus says their use on assembly lines should "help operators in the dreariest and physically exhausting stages of the production process, allowing highly qualified staff to carry out tasks that create added value."

Sales of such robots in the next four years should increase from $ 100 million to nearly $ 3 billion, predicts James Stettler, analyst at Barclays. Eventually they may take half the global robots market worth $ 32 billion, said Andreas Bauer, head of strategic marketing of Kuka robots producer, and chairman of suppliers committee in the International Federation of Robotics.

So far, few companies are thinking about future of robots in manufacture. Airbus, however, hopes that the developed robots will be able to work in remote parts of the aircraft. To make sure the machines are able to perform a variety of functions, their algorithms will be tested on real assignments in different departments of Airbus. "We want to see these robots perform the most physically difficult tasks that require, for example, to raise your hands and keep them high above the head for a long time, or go down very low. Workers do not want to do this kind of work, and the robots will help them - said participating in the project Adrien Escande. - We have already demonstrated potential of these robots, and now we must now prove their industrial reliability."

Not only Airbus, but also its US rival Boeing is increasing level of automation on the production. The companies are trying to make their plants more efficient to deal with a large volume of orders. In the next five years, Airbus plans to introduce new technologies every year. In late 2015, the company launched testing of small wheeled robots that move inside the fuselage together with the workers. In turn, Boeing uses controlled robots for production of fuselages of passenger planes. The robots are put on a platform inside the aircraft to install more than 60,000 fasteners instead of people.

source: ft.com

Sales of such robots in the next four years should increase from $ 100 million to nearly $ 3 billion, predicts James Stettler, analyst at Barclays. Eventually they may take half the global robots market worth $ 32 billion, said Andreas Bauer, head of strategic marketing of Kuka robots producer, and chairman of suppliers committee in the International Federation of Robotics.

So far, few companies are thinking about future of robots in manufacture. Airbus, however, hopes that the developed robots will be able to work in remote parts of the aircraft. To make sure the machines are able to perform a variety of functions, their algorithms will be tested on real assignments in different departments of Airbus. "We want to see these robots perform the most physically difficult tasks that require, for example, to raise your hands and keep them high above the head for a long time, or go down very low. Workers do not want to do this kind of work, and the robots will help them - said participating in the project Adrien Escande. - We have already demonstrated potential of these robots, and now we must now prove their industrial reliability."

Not only Airbus, but also its US rival Boeing is increasing level of automation on the production. The companies are trying to make their plants more efficient to deal with a large volume of orders. In the next five years, Airbus plans to introduce new technologies every year. In late 2015, the company launched testing of small wheeled robots that move inside the fuselage together with the workers. In turn, Boeing uses controlled robots for production of fuselages of passenger planes. The robots are put on a platform inside the aircraft to install more than 60,000 fasteners instead of people.

source: ft.com