Prostheses, auto parts and aircraft parts - all of this in the near future will be printed on an industrial scale, believe experts of The Boston Consulting Group (BCG). They say that the 3D printing market will amount to $ 15 billion against the current $ 5 billion by 2020, and half of this volume will fall on three sectors - aerospace, automotive and medical (especially dentistry).

Now, 3D printing is experiencing a transition to industrial use. In the coming years, this sector will be growing by around 30% annually, which will allow the 3D market to more than triple by 2021. If companies introduce 3D printing to at least 1.5% of total production by 2035, the market’s volume will exceed $ 350 billion by then.

Experts say that 3D printing would be more relevant for a new production rather than for replacing existing ones. For example, production and repair of spare parts are poorly developed in the aerospace industry. It is possible that the three-dimensional printing could accelerate development of this direction.

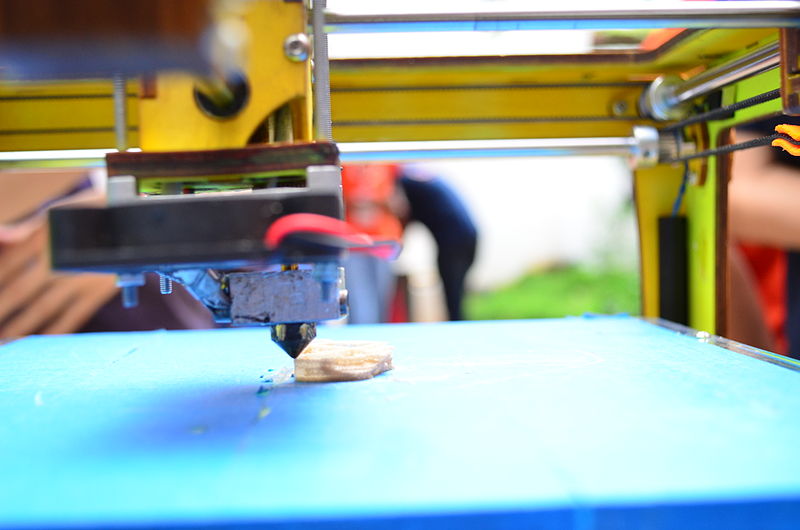

3D-printers have existed for several years, and projects to create new items are popping up nearly every day. However, these devices still cannot find their place in the industrial production - firstly, because of its high cost, and secondly, because the process itself takes much more time than convenient ways of production. In addition, now most of the printers create an object layer by layer, applying one layer of material to another, which makes the final product unstable to serious overloads. However, this does not mean that large manufacturing companies are not looking for ways to resolve all these problems. Moreover, they have achieved some success in this field.

One of the leaders of the world automotive industry, American company Ford, is actively cooperating with Carbon3D Inc., a startup, supported by financial division of Alphabet Google Ventures. The automaker is already testing Carbon3D’s printers in its labs. Representatives of Ford itself say that it would be a solution to all problems inherent in the original technology of 3D printing.

Ford is not the only major company currently engaged in the search for a way to introduce bulk printing technology into mass production. For example, General Electric stated that it intends to 3D-print up to 200 thousand fuel pistols for its aviation business. Recently, the company’s management announced creation of a special research center in Pittsburgh, which will focus on search for possible application of the new technology in all business structures of the American corporation.

Now the world is annually spending $ 1.5 billion on research in the field of 3D printing. For comparison, the figure was just $ 406 million at the dawn of appearance of printers capable of performing volumetric printing. Companies around the world will spend about $ 4 billion on R&D in this area in 2017, says research agency Gartner.

source: bcg.com

Now, 3D printing is experiencing a transition to industrial use. In the coming years, this sector will be growing by around 30% annually, which will allow the 3D market to more than triple by 2021. If companies introduce 3D printing to at least 1.5% of total production by 2035, the market’s volume will exceed $ 350 billion by then.

Experts say that 3D printing would be more relevant for a new production rather than for replacing existing ones. For example, production and repair of spare parts are poorly developed in the aerospace industry. It is possible that the three-dimensional printing could accelerate development of this direction.

3D-printers have existed for several years, and projects to create new items are popping up nearly every day. However, these devices still cannot find their place in the industrial production - firstly, because of its high cost, and secondly, because the process itself takes much more time than convenient ways of production. In addition, now most of the printers create an object layer by layer, applying one layer of material to another, which makes the final product unstable to serious overloads. However, this does not mean that large manufacturing companies are not looking for ways to resolve all these problems. Moreover, they have achieved some success in this field.

One of the leaders of the world automotive industry, American company Ford, is actively cooperating with Carbon3D Inc., a startup, supported by financial division of Alphabet Google Ventures. The automaker is already testing Carbon3D’s printers in its labs. Representatives of Ford itself say that it would be a solution to all problems inherent in the original technology of 3D printing.

Ford is not the only major company currently engaged in the search for a way to introduce bulk printing technology into mass production. For example, General Electric stated that it intends to 3D-print up to 200 thousand fuel pistols for its aviation business. Recently, the company’s management announced creation of a special research center in Pittsburgh, which will focus on search for possible application of the new technology in all business structures of the American corporation.

Now the world is annually spending $ 1.5 billion on research in the field of 3D printing. For comparison, the figure was just $ 406 million at the dawn of appearance of printers capable of performing volumetric printing. Companies around the world will spend about $ 4 billion on R&D in this area in 2017, says research agency Gartner.

source: bcg.com